Precision Tooling and Machining Services for Industry Leaders

- meghanhicks1

- May 9

- 5 min read

In today's fast-paced industrial landscape, precision is not just a luxury; it is a necessity. Companies that lead the way in their respective fields understand the importance of high-quality tooling and machining services. These services are crucial for creating parts that meet exact specifications, ensuring efficiency and reliability in production.

Precision tooling and machining services are the backbone of many industries, from aerospace to automotive. They help businesses maintain a competitive edge by delivering products that are not only functional but also durable. In this blog post, we will explore the significance of precision tooling and machining services, the technologies involved, and how industry leaders can benefit from these services.

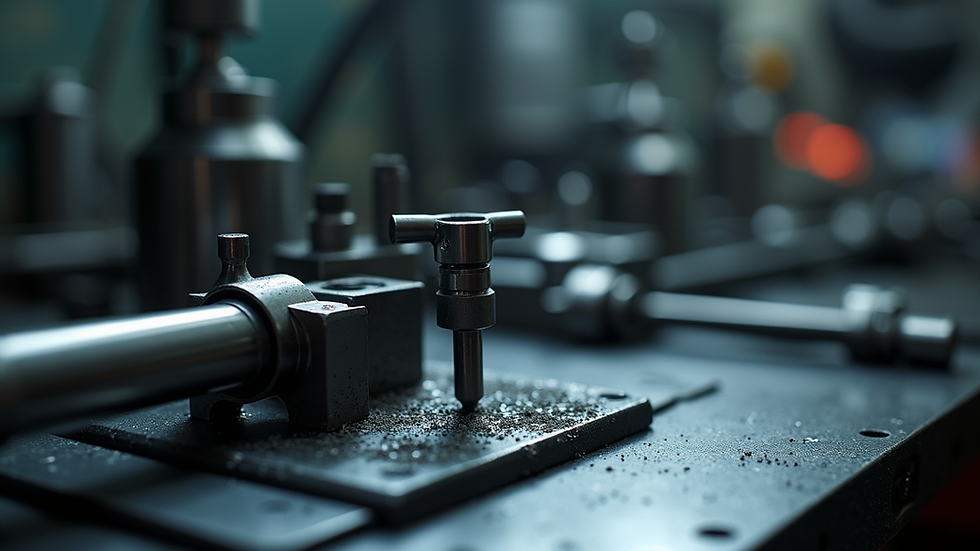

Understanding Precision Tooling

Precision tooling refers to the creation of tools that are used in manufacturing processes. These tools are designed to produce parts with high accuracy and repeatability. The importance of precision tooling cannot be overstated.

Quality Assurance: Precision tools ensure that every part produced meets strict quality standards. This is vital in industries where safety is paramount, such as aerospace and medical devices.

Cost Efficiency: By using precision tools, companies can reduce waste and minimize errors. This leads to lower production costs and higher profit margins.

Customization: Precision tooling allows for the creation of custom tools tailored to specific manufacturing needs. This flexibility can be a game-changer for businesses looking to innovate.

Precision tooling is not just about creating tools; it is about creating tools that work perfectly every time.

The Role of Machining Services

Machining services complement precision tooling by shaping and finishing materials to create the final product. Machining involves various processes, including turning, milling, and grinding. Each of these processes plays a crucial role in achieving the desired specifications.

Turning: This process involves rotating a workpiece while a cutting tool removes material. It is commonly used for creating cylindrical parts.

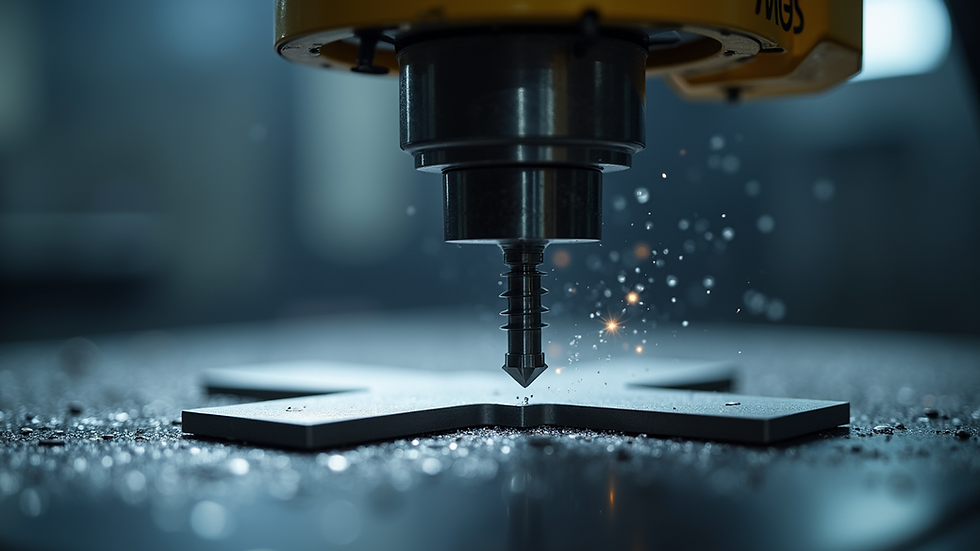

Milling: In milling, a rotating cutter removes material from a stationary workpiece. This method is versatile and can create complex shapes.

Grinding: Grinding is used for finishing surfaces to achieve a high level of smoothness and precision. It is often the final step in the machining process.

By utilizing advanced machining services, companies can ensure that their products are not only precise but also of the highest quality.

Technologies Driving Precision Tooling and Machining

The world of precision tooling and machining is constantly evolving. New technologies are emerging that enhance the capabilities of these services. Here are some key technologies that industry leaders should be aware of:

CNC Machining: Computer Numerical Control (CNC) machining allows for automated control of machining tools. This technology increases precision and reduces the risk of human error.

3D Printing: Additive manufacturing, or 3D printing, is revolutionizing the way parts are produced. It allows for rapid prototyping and the creation of complex geometries that traditional methods cannot achieve.

Laser Cutting: Laser cutting provides high precision and clean edges. It is ideal for materials that require intricate designs.

These technologies not only improve the quality of the products but also speed up the production process.

Benefits for Industry Leaders

Industry leaders who invest in precision tooling and machining services can reap numerous benefits. Here are some of the key advantages:

Enhanced Product Quality: With precision tooling and machining, companies can produce parts that meet the highest quality standards. This leads to increased customer satisfaction and loyalty.

Faster Time to Market: By utilizing advanced technologies, companies can reduce the time it takes to develop and produce new products. This agility is crucial in today’s competitive market.

Increased Profitability: Lower production costs and higher quality products lead to increased profitability. Companies can achieve better margins and reinvest in innovation.

Sustainability: Precision tooling and machining can lead to less waste and more efficient use of materials. This aligns with the growing demand for sustainable practices in manufacturing.

Investing in these services is not just about keeping up; it is about leading the way in innovation and quality.

Case Studies: Success Stories

To illustrate the impact of precision tooling and machining services, let’s look at a few success stories from industry leaders.

Aerospace Industry

A leading aerospace manufacturer faced challenges with producing lightweight components that met strict safety regulations. By investing in precision tooling and CNC machining, they were able to create parts that were not only lighter but also stronger. This innovation allowed them to reduce fuel consumption in their aircraft, leading to significant cost savings and a smaller environmental footprint.

Automotive Sector

An automotive company struggled with high defect rates in their engine components. They turned to precision machining services to improve their manufacturing process. By implementing advanced milling and grinding techniques, they reduced defects by over 30%. This improvement not only enhanced product quality but also boosted their reputation in the market.

Medical Devices

A medical device manufacturer needed to produce intricate components for surgical instruments. They utilized 3D printing technology to create prototypes quickly. This allowed them to test and refine their designs before moving to full-scale production. The result was a faster time to market and a product that met the exact needs of healthcare professionals.

These case studies highlight how precision tooling and machining services can transform businesses and drive success.

Choosing the Right Partner

Selecting the right partner for precision tooling and machining services is crucial. Here are some factors to consider:

Experience: Look for a company with a proven track record in your industry. Experience often translates to better quality and reliability.

Technology: Ensure that the partner uses the latest technologies. This will help you stay competitive and meet the demands of your customers.

Customization: Choose a partner that offers tailored solutions. Your needs may vary, and having a partner that can adapt is essential.

Customer Support: Good communication and support are vital. You want a partner that is responsive and willing to work with you throughout the process.

By carefully selecting a partner, you can ensure that your precision tooling and machining needs are met effectively.

The Future of Precision Tooling and Machining

As technology continues to advance, the future of precision tooling and machining looks promising. Here are some trends to watch:

Automation: The rise of automation will further enhance efficiency and precision in manufacturing processes.

Smart Manufacturing: The integration of IoT (Internet of Things) will allow for real-time monitoring and data analysis, leading to better decision-making.

Sustainability: There will be a greater focus on sustainable practices, with companies looking for ways to reduce their environmental impact.

Collaboration: Industry leaders will increasingly collaborate with technology providers to innovate and improve their processes.

Staying ahead of these trends will be essential for companies looking to maintain their leadership position in the market.

Final Thoughts

Precision tooling and machining services are vital for industry leaders who want to excel in their fields. By investing in these services, companies can enhance product quality, reduce costs, and improve efficiency.

As technology continues to evolve, the opportunities for innovation are endless. Embracing these advancements will not only benefit individual companies but also contribute to the overall growth of the industry.

In a world where precision is key, the right tooling and machining services can make all the difference.

Comments