Maximizing Efficiency with Advanced CNC Machines

- meghanhicks1

- May 9

- 4 min read

In today's fast-paced manufacturing world, efficiency is key. Companies are always looking for ways to improve their production processes. One of the most effective ways to achieve this is through the use of advanced CNC (Computer Numerical Control) machines. These machines have revolutionized the manufacturing industry, allowing for precision, speed, and flexibility. In this blog post, we will explore how to maximize efficiency with advanced CNC machines, providing practical tips and insights along the way.

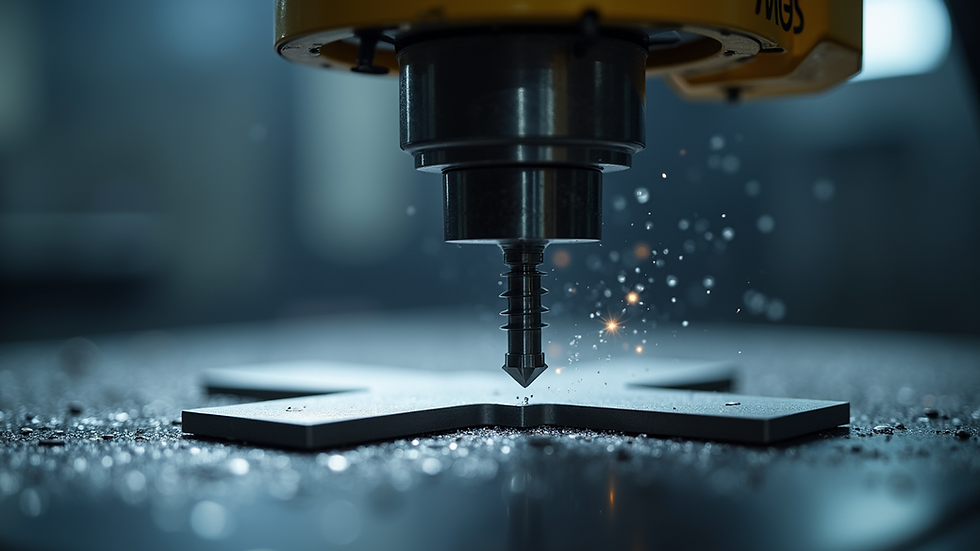

Understanding CNC Machines

CNC machines are automated tools that use computer programming to control their movements. They can cut, shape, and finish materials with incredible accuracy. This technology has transformed traditional manufacturing methods, making it possible to produce complex parts quickly and consistently.

CNC machines come in various types, including milling machines, lathes, and routers. Each type serves a specific purpose, but they all share the same fundamental principle of automation and precision.

Benefits of Advanced CNC Machines

Using advanced CNC machines offers several benefits that can significantly enhance efficiency in manufacturing. Here are some key advantages:

Precision: CNC machines can produce parts with tight tolerances, reducing the need for rework and scrap.

Speed: Automated processes allow for faster production times, enabling companies to meet tight deadlines.

Flexibility: CNC machines can be easily reprogrammed for different tasks, making it simple to switch between projects.

Consistency: Once programmed, CNC machines can produce identical parts repeatedly, ensuring quality control.

Reduced Labor Costs: Automation reduces the need for manual labor, allowing companies to allocate resources more effectively.

Choosing the Right CNC Machine

Selecting the right CNC machine is crucial for maximizing efficiency. Here are some factors to consider:

Type of Material: Different machines are designed for specific materials. For example, a CNC router is ideal for wood, while a CNC mill is better suited for metals.

Size and Capacity: Consider the size of the parts you will be producing. Ensure the machine can accommodate your largest workpiece.

Software Compatibility: Ensure the CNC machine is compatible with your existing software. This will streamline the programming process.

Budget: Advanced CNC machines can be a significant investment. Determine your budget and look for machines that offer the best value for your needs.

Optimizing CNC Machine Operations

Once you have selected the right CNC machine, it is essential to optimize its operations. Here are some practical tips:

Regular Maintenance

Regular maintenance is vital for keeping CNC machines running smoothly. Schedule routine checks to ensure all components are functioning correctly. This can prevent unexpected breakdowns and costly downtime.

Efficient Tool Management

Using the right tools for each job can enhance efficiency. Keep an organized inventory of tools and ensure they are in good condition. Consider investing in tool management software to track usage and maintenance.

Optimize Cutting Parameters

Adjusting cutting parameters such as speed, feed rate, and depth of cut can significantly impact efficiency. Experiment with different settings to find the optimal combination for your specific materials and designs.

Implement Automation

Consider integrating automation into your CNC operations. This can include robotic arms for loading and unloading materials or automated tool changers. Automation can reduce manual labor and increase production speed.

Utilize Simulation Software

Before running a new program, use simulation software to visualize the machining process. This can help identify potential issues and optimize the program before actual production begins.

Training and Skill Development

Investing in training for your operators is essential for maximizing the efficiency of CNC machines. Well-trained operators can troubleshoot issues quickly and make adjustments on the fly. Here are some training tips:

Hands-On Training: Provide operators with hands-on experience to familiarize them with the machines.

Continuous Learning: Encourage ongoing education and training to keep operators updated on the latest technologies and techniques.

Cross-Training: Train operators on multiple machines to increase flexibility and adaptability in your workforce.

Real-World Examples

To illustrate the impact of advanced CNC machines on efficiency, let’s look at a couple of real-world examples.

Example 1: Aerospace Industry

In the aerospace industry, precision is critical. A leading aerospace manufacturer implemented advanced CNC machines to produce complex components for aircraft. By using CNC milling machines, they reduced production time by 30% while maintaining strict quality standards. The ability to quickly switch between different parts also allowed them to respond to customer demands more effectively.

Example 2: Furniture Manufacturing

A furniture manufacturer adopted CNC routers to streamline their production process. By automating the cutting and shaping of wood, they increased their output by 50%. The precision of the CNC machines also reduced waste, allowing them to use materials more efficiently. This not only improved their bottom line but also contributed to sustainability efforts.

The Future of CNC Technology

As technology continues to evolve, so does the potential for CNC machines. Here are some trends to watch for in the future:

Integration with IoT: The Internet of Things (IoT) will enable CNC machines to communicate with other devices, allowing for real-time monitoring and data analysis.

Advanced Materials: New materials, such as composites and advanced alloys, will require CNC machines to adapt and evolve.

Artificial Intelligence: AI can enhance CNC programming and operations, making machines smarter and more efficient.

Sustainability: As manufacturers focus on sustainability, CNC machines will play a crucial role in reducing waste and energy consumption.

Final Thoughts

Maximizing efficiency with advanced CNC machines is not just about investing in the latest technology. It involves a holistic approach that includes selecting the right machines, optimizing operations, and investing in training. By embracing these strategies, manufacturers can enhance productivity, reduce costs, and stay competitive in a rapidly changing market.

As the manufacturing landscape continues to evolve, those who adapt and innovate will thrive. Advanced CNC machines are a powerful tool in this journey, offering the precision and efficiency needed to meet the demands of today and tomorrow.

Comments