Innovative Injection Molding Solutions for Manufacturing Success

- meghanhicks1

- May 9

- 5 min read

In today's fast-paced manufacturing world, staying ahead of the competition is crucial. One of the most effective ways to achieve this is through innovative injection molding solutions. This technology has transformed how products are made, offering efficiency, precision, and versatility. In this blog post, we will explore the latest advancements in injection molding, how they can benefit your manufacturing processes, and real-world examples of success.

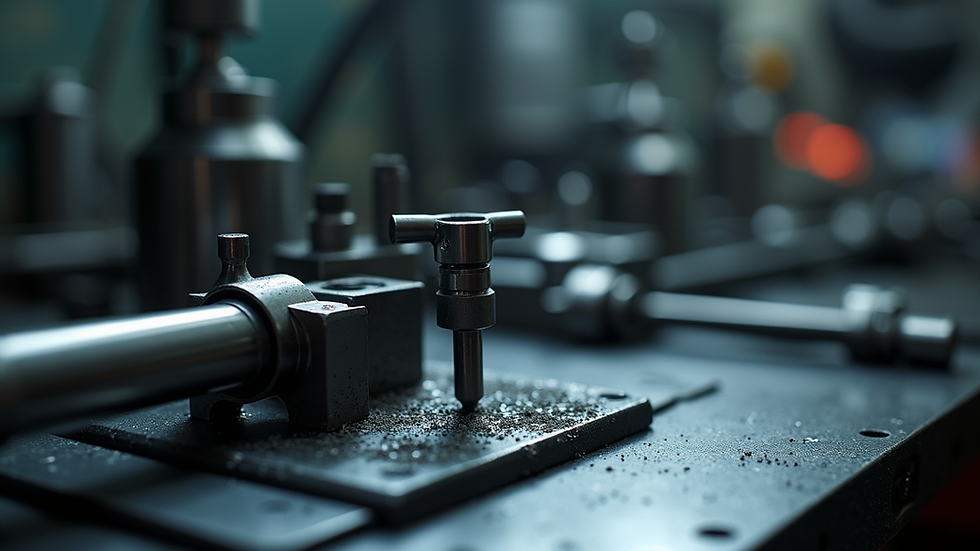

Understanding Injection Molding

Injection molding is a manufacturing process used to create parts by injecting molten material into a mold. This method is widely used for producing plastic parts, but it can also work with metals, glass, and ceramics. The process involves several key steps:

Material Selection: Choosing the right material is essential. Common materials include thermoplastics, thermosets, and elastomers.

Mold Design: A well-designed mold is critical for achieving the desired shape and quality of the final product.

Injection Process: The molten material is injected into the mold under high pressure, allowing it to fill every cavity.

Cooling and Ejection: Once the material cools and solidifies, the mold opens, and the finished part is ejected.

This process allows for high-volume production with minimal waste, making it a popular choice in various industries.

The Benefits of Innovative Injection Molding Solutions

Innovative injection molding solutions offer numerous advantages that can lead to manufacturing success. Here are some key benefits:

1. Cost Efficiency

One of the most significant advantages of injection molding is its cost efficiency. Once the mold is created, producing each part becomes relatively inexpensive. This is especially true for high-volume production runs, where the cost per unit decreases significantly.

2. Design Flexibility

Modern injection molding techniques allow for greater design flexibility. Manufacturers can create complex shapes and intricate details that were once difficult or impossible to achieve. This flexibility enables companies to innovate and differentiate their products in the market.

3. High Precision and Quality

Injection molding provides high precision and consistent quality. The process allows for tight tolerances, ensuring that each part meets the required specifications. This level of accuracy is crucial in industries such as automotive and medical, where even minor defects can lead to significant issues.

4. Reduced Waste

Innovative injection molding solutions often incorporate advanced technologies that minimize waste. For example, using recycled materials or optimizing the mold design can significantly reduce scrap rates. This not only benefits the environment but also lowers production costs.

5. Faster Production Times

With advancements in technology, injection molding processes have become faster. Automated systems and improved machinery allow for quicker cycle times, enabling manufacturers to meet tight deadlines and respond to market demands more effectively.

Emerging Technologies in Injection Molding

As the manufacturing landscape evolves, so do the technologies used in injection molding. Here are some of the most exciting innovations currently shaping the industry:

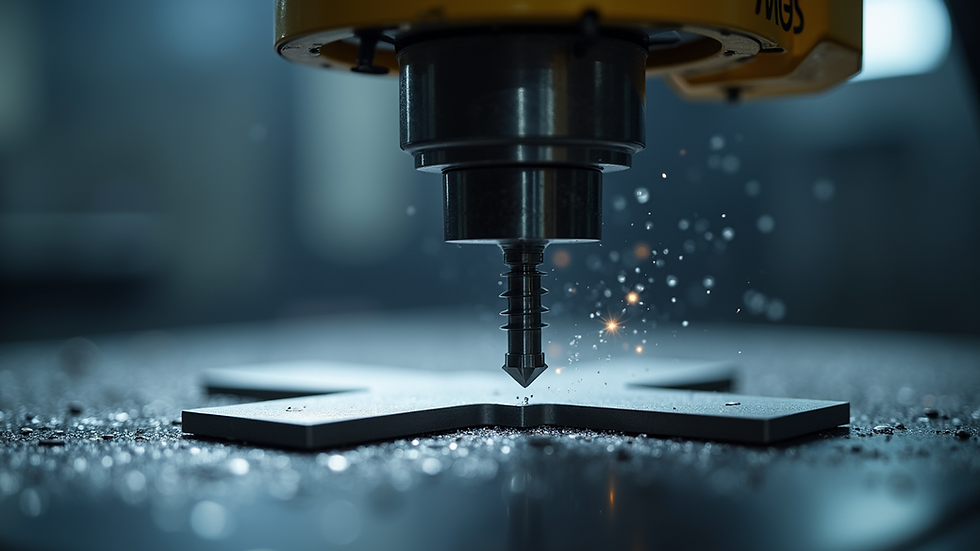

1. 3D Printing and Injection Molding

3D printing has made waves in manufacturing, and its integration with injection molding is a game-changer. Companies can use 3D printing to create prototypes and molds quickly. This speeds up the design process and allows for rapid testing and iteration.

2. Smart Manufacturing

The rise of Industry 4.0 has brought smart manufacturing to the forefront. Injection molding machines equipped with IoT sensors can monitor performance in real-time. This data helps manufacturers optimize processes, predict maintenance needs, and improve overall efficiency.

3. Biodegradable Materials

Sustainability is a growing concern in manufacturing. Innovative injection molding solutions now include the use of biodegradable materials. These materials break down more easily in the environment, reducing the ecological impact of plastic products.

4. Multi-Material Injection Molding

Multi-material injection molding allows manufacturers to combine different materials in a single part. This technique can enhance product functionality and aesthetics, providing a competitive edge in the market.

5. Advanced Mold Technologies

New mold technologies, such as conformal cooling and hot runner systems, improve the injection molding process. These advancements lead to better temperature control, reduced cycle times, and improved part quality.

Real-World Examples of Success

To illustrate the impact of innovative injection molding solutions, let's look at a few real-world examples.

Example 1: Automotive Industry

A leading automotive manufacturer implemented advanced injection molding techniques to produce lightweight components. By using multi-material injection molding, they created parts that combined strength and reduced weight. This innovation not only improved fuel efficiency but also enhanced vehicle performance.

Example 2: Consumer Electronics

A consumer electronics company adopted 3D printing for rapid prototyping and mold creation. This approach allowed them to bring new products to market faster. By reducing the time spent on design and testing, they gained a significant advantage over competitors.

Example 3: Medical Devices

In the medical field, precision is paramount. A medical device manufacturer utilized smart manufacturing technologies in their injection molding processes. By monitoring machine performance in real-time, they reduced defects and ensured compliance with strict regulatory standards.

Challenges in Injection Molding

While innovative injection molding solutions offer many benefits, there are also challenges to consider. Here are some common issues manufacturers may face:

1. High Initial Costs

The initial investment in mold design and machinery can be high. However, this cost is often offset by the long-term savings achieved through efficient production.

2. Complexity of Mold Design

Creating a mold that meets all design specifications can be complex. It requires skilled engineers and designers to ensure that the mold functions correctly and produces high-quality parts.

3. Material Limitations

Not all materials are suitable for injection molding. Manufacturers must carefully select materials that can withstand the injection process and meet the desired performance criteria.

4. Maintenance and Downtime

Like any machinery, injection molding equipment requires regular maintenance. Downtime for repairs can impact production schedules and lead to increased costs.

The Future of Injection Molding

The future of injection molding looks promising, with continued advancements on the horizon. As technology evolves, manufacturers can expect even greater efficiency, sustainability, and customization options. Here are a few trends to watch:

1. Increased Automation

Automation will play a significant role in the future of injection molding. More manufacturers will adopt robotic systems to handle tasks such as material loading, part removal, and quality inspection.

2. Enhanced Sustainability Practices

Sustainability will remain a key focus. Manufacturers will increasingly seek ways to reduce their environmental impact, from using recycled materials to implementing energy-efficient processes.

3. Greater Customization

As consumer preferences shift towards personalized products, injection molding will adapt. Manufacturers will leverage advanced technologies to offer more customization options, allowing customers to tailor products to their needs.

4. Integration with Other Technologies

The integration of injection molding with other manufacturing technologies, such as additive manufacturing and CNC machining, will create new possibilities. This hybrid approach can lead to innovative product designs and improved production efficiency.

Embracing Innovation for Manufacturing Success

In conclusion, innovative injection molding solutions are transforming the manufacturing landscape. By embracing these advancements, companies can achieve greater efficiency, reduce costs, and enhance product quality. The benefits of injection molding are clear, and the future holds even more exciting possibilities.

As manufacturers continue to explore new technologies and techniques, those who adapt and innovate will undoubtedly find success in this competitive industry. Whether you are in the automotive, consumer electronics, or medical field, now is the time to invest in innovative injection molding solutions and reap the rewards.

Comments